Info:Introducing the world - first integrated EMU - shaped design of the washing system. Its modules feature independent frequency conversion control and strong maneuverability. The unique 360 - degree circumferential washing combined with 270 - degree sw......

Models:洗衣龙系列

Models:洗衣龙系列 View:

View:Product

ProductDetailed Introduction

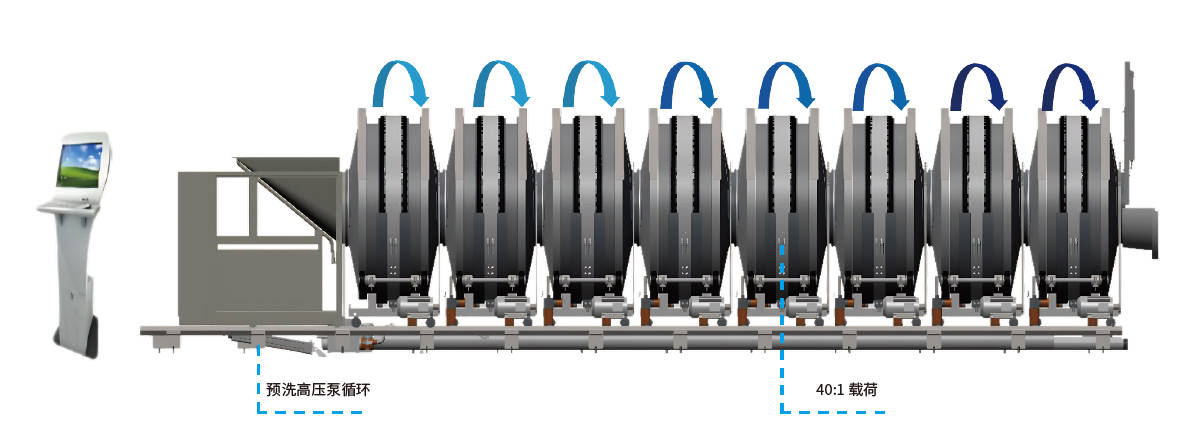

The globally pioneering integrated high-speed train design for washing systems incorporates innovative concepts from high-speed trains into washing equipment, bringing revolutionary changes to the industrial laundry sector.

Enhanced Flexibility and Mobility:

In terms of mobility, this washing system offers significant advantages. Each module features independent variable frequency control, allowing rotational speed to be flexibly adjusted between 7-15 rpm. This enables the washing process to be dynamically tailored based on factors such as fabric type and soil level. For example, delicate silk fabrics can be washed at lower speeds with gentler modes to prevent damage, while heavily soiled workwear can be processed at higher speeds for better cleaning. The independent module design also simplifies maintenance, as only the faulty module needs attention without extensive disassembly. Additionally, production capacity can be easily expanded by adding more modules to meet growing demand.

Superior Washing Performance:

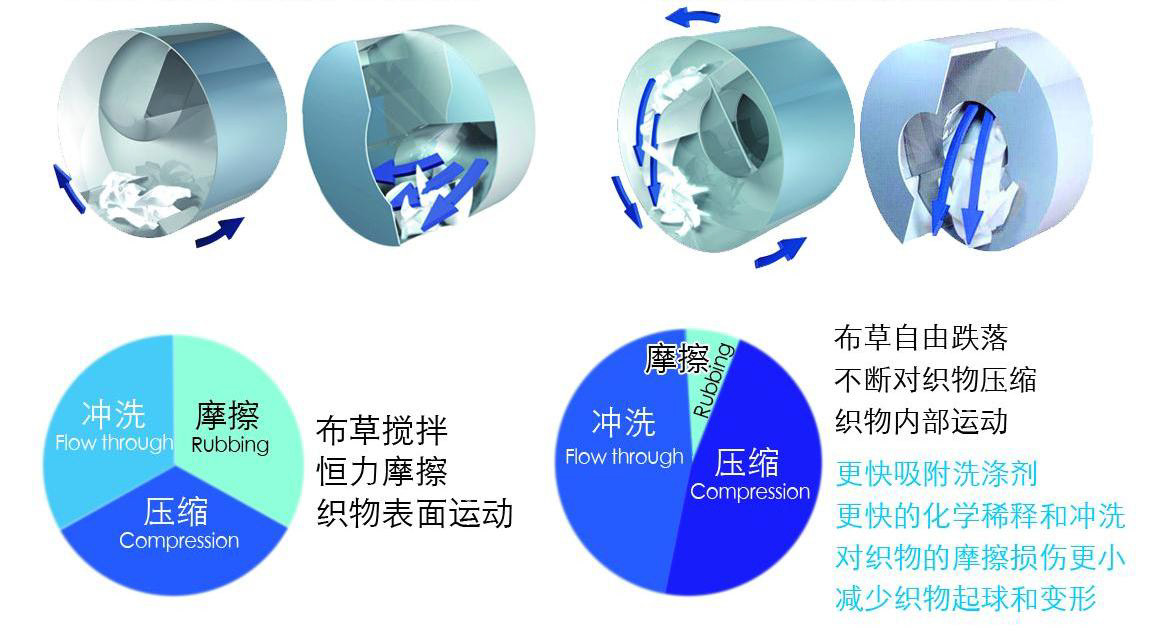

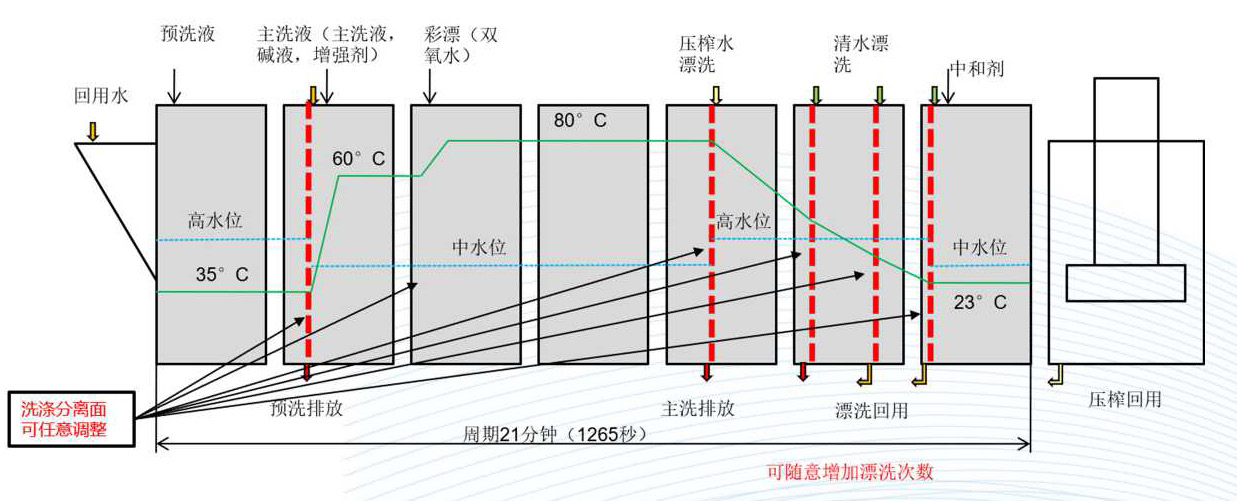

Washing performance is a critical metric for laundry equipment, and this system excels in this regard. It employs a unique 360-degree circumferential washing method combined with a 270-degree oscillating washing technique. The 360-degree method ensures fabrics tumble thoroughly inside the drum, similar to clothes in a washing machine, allowing every part to be cleaned effectively. Meanwhile, the 270-degree oscillating method enhances cleaning through flushing and compression. For instance, hotel bed linens can have stains removed more thoroughly. The pre-wash pump circulation system continuously recycles washing liquid, maintaining strong decontamination power. With a large load ratio of 40:1, the drum accommodates more fabric while providing ample tumbling space, delivering higher washing performance—ideal for demanding clients like high-end hotels and hospitals.

Greater Energy Efficiency:

This washing system also stands out in energy savings. Its soft-connected outer drum reduces vibration energy loss during operation. The multi-stage circulation pumps, especially the high-pressure pump design in the first chamber, optimize water and energy usage. Compared to traditional tunnel washers, it saves over 30% in energy consumption. The intelligent circulation system minimizes fresh water intake, while the optimized pump and drive mechanisms reduce electricity and heat requirements, ensuring an energy-efficient washing process.

Exclusive 360-degree patented washing technology: This technology delivers stronger tumbling and compression, significantly enhancing mechanical washing action. Fabrics freely fall inside the drum, fully interacting with washing liquid while undergoing compression, ensuring higher cleanliness—critical for hospitals with stringent hygiene standards.

Large 2000mm diameter drum: The extended free-fall path increases mechanical washing force. For example, surgical gowns can fully unfold during washing, ensuring thorough cleaning of all areas.

40:1 large load ratio: As mentioned, this allows fabrics more tumbling space. When washing large quantities of hotel towels, each towel receives adequate cleaning, avoiding incomplete washing due to overcrowding.

Independent modular chambers: On-site assembly offers installation flexibility, suitable for basements or multi-story factories. Businesses can start with a 5-chamber configuration and expand to 7, 8, or 10 chambers as needed, reducing initial investment costs.

Dual-chamber, dual-pipeline water inlet/outlet per chamber: This enables customized washing programs for different fabrics. For example, white bed linens and colored towels can be washed separately with tailored water temperatures, levels, and detergent doses for optimal results.

15-minute quick chamber disassembly: In case of blockages, chambers can be swiftly disassembled for inspection or cleaning, addressing a common maintenance challenge in traditional tunnel washers and minimizing downtime.

Premium S304+ stainless steel construction: Key components like the inner drum, outer shell, frame, rails, base, water tank, and pipelines are made of high-quality stainless steel, ensuring corrosion resistance, durability, and long-term stability in high-load environments—reducing replacement and maintenance costs.

Additionally, the speed of each chamber can be flexibly adjusted via variable frequency control within the range of 7-15 rpm, achieving different washing effects while maintaining balanced cycle times. Through precise speed control of individual chambers, the system can optimize the washing process for different fabrics and stages.

Pre-wash stage: The speed can be increased appropriately to quickly remove large surface stains.

Main wash stage: The speed is adjusted based on fabric type and soil level to achieve optimal cleaning.

Rinse stage: The speed is reduced to conserve water while ensuring thorough rinsing.

The tunnel washer’s high-capacity batch processing gives it a unique advantage in industrial laundry applications. It combines the operational flexibility of standalone machines with superior cleaning power.

Larger load ratio ensures more efficient processing.

Variable frequency adjustment for each segment allows customized washing intensity.

Dual-action flushing and compression increase mechanical force, delivering better cleaning results.

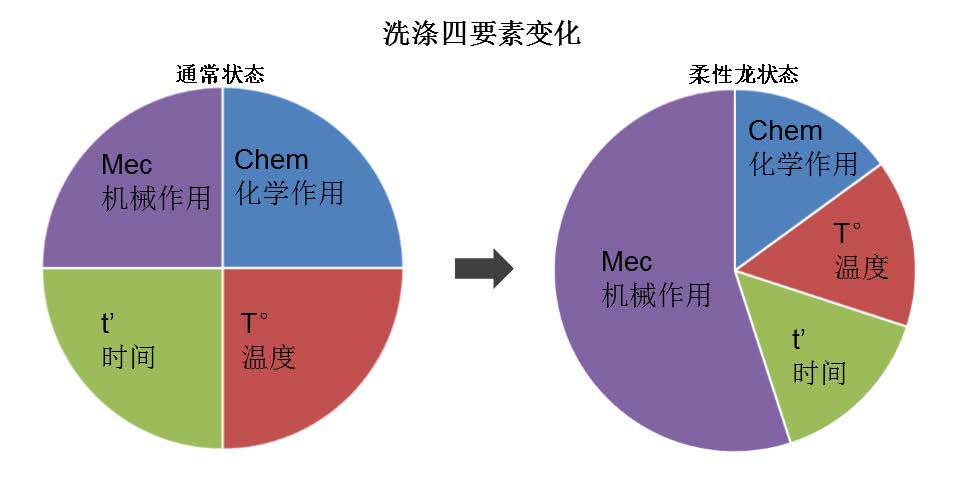

Due to its strong mechanical action, the system reduces reliance on other washing factors such as detergent dosage, washing time, and temperature, thereby speeding up the entire process.

Example: When washing large quantities of hospital patient gowns, the tunnel washer can complete the task quickly with excellent cleaning results while using less detergent, minimizing environmental impact.

According to authoritative evaluations by professional institutions, the 360-degree circumferential washing method demonstrates significant advantages over the 270-degree oscillating washing method in terms of mechanical action and cleaning performance.

The 360-degree washing technology subjects fabrics to more comprehensive and forceful agitation during the cycle. Compared to traditional 270-degree oscillation, it ensures more thorough stain removal, higher washing efficiency, while also reducing fabric wear and deformation.

This washing system offers the flexibility to customize washing programs just like standalone machines, achieving impeccable cleaning results.

Take the medical linen program as an example:

Configuration: 7 chambers × 75kg

Unloading cycle: 3 minutes (180 seconds)

Hourly capacity: 1,500kg

Post-wash test data demonstrates outstanding performance:

Residual alkali (active alkali): <20 PPM

pH level: 6.5–6.9

Rewash rate: Only 1.1%–1.3%

These results confirm the system’s high-efficiency washing capability and consistent cleaning quality, meeting the stringent requirements of the medical industry for linen hygiene.

| Diameter (mm) | Washing angle | Lifting height (mm) | Volume load (Volume/Load) | Diameter-depth ratio (Diameter/Depth) | Minimum washing mechanical force | Maximum washing mechanical force | Effect |

|---|---|---|---|---|---|---|---|

| 2000 | 360 | 1800 | 40: 1 | 2.83 | 0.12 | 0.36 (18rpm) | Greater mechanical action |

| Competitive Advantages of the Flexible Drum Washer (Compared with Other Drum Washers) | ||

|---|---|---|

| Performance Advantages | 360-degree washing with high mechanical force ensures a higher degree of cleanliness. | It solves the problems of common drum washing machines, such as ineffective cleaning, inability to perform mixed washing, and difficulties in maintenance and expansion |

| With full double bins and frequency conversion control, it has stronger washing adaptability and maneuverability, and mixed washing is possible. | ||

| The modular combination structure makes it convenient to use and maintain, and the production capacity can be expanded | ||

| Economic Advantages | Water consumption is 50% less than that of other systems. | Compared with ordinary drum - type (washing machines), it has more economic advantages and can reduce operating costs |

| Steam consumption is 20% less than that of other systems. | ||

| Chemical consumption is 30% less than that of other systems. | ||

| Advantages of improvement | The compartmentalized frequency conversion control, combined with the swaying washing method, can adjust | Compared with modular drum - type (washing machines) |

| The washing speed and various parameters according to different fabrics, achieving flexible washing | ||

| The volume-load ratio is as high as 40:1, providing sufficient washing space and enhancing the cleaning power | ||

| The overall closed arc-top appearance comes with an observation window | ||

| The control operating system based on WIN7 has remote control and data management functions | ||

Product Consultation

+86 158-2025-1513

1744149454@qq.com

No. 2, Xinghai Road, Lanhe Town, Nansha District, Guangzhou, China

Product

News Center

Copyright