Info:The integrated fully automatic washing system (integrated fully automatic production line) is adapted to large-batch washing methods. It uses a central control system and logistics system to connect individual machines, enabling the equipment to oper......

Models:集成式全自动洗涤系统

Models:集成式全自动洗涤系统 View:

View:Product

ProductDetailed Introduction

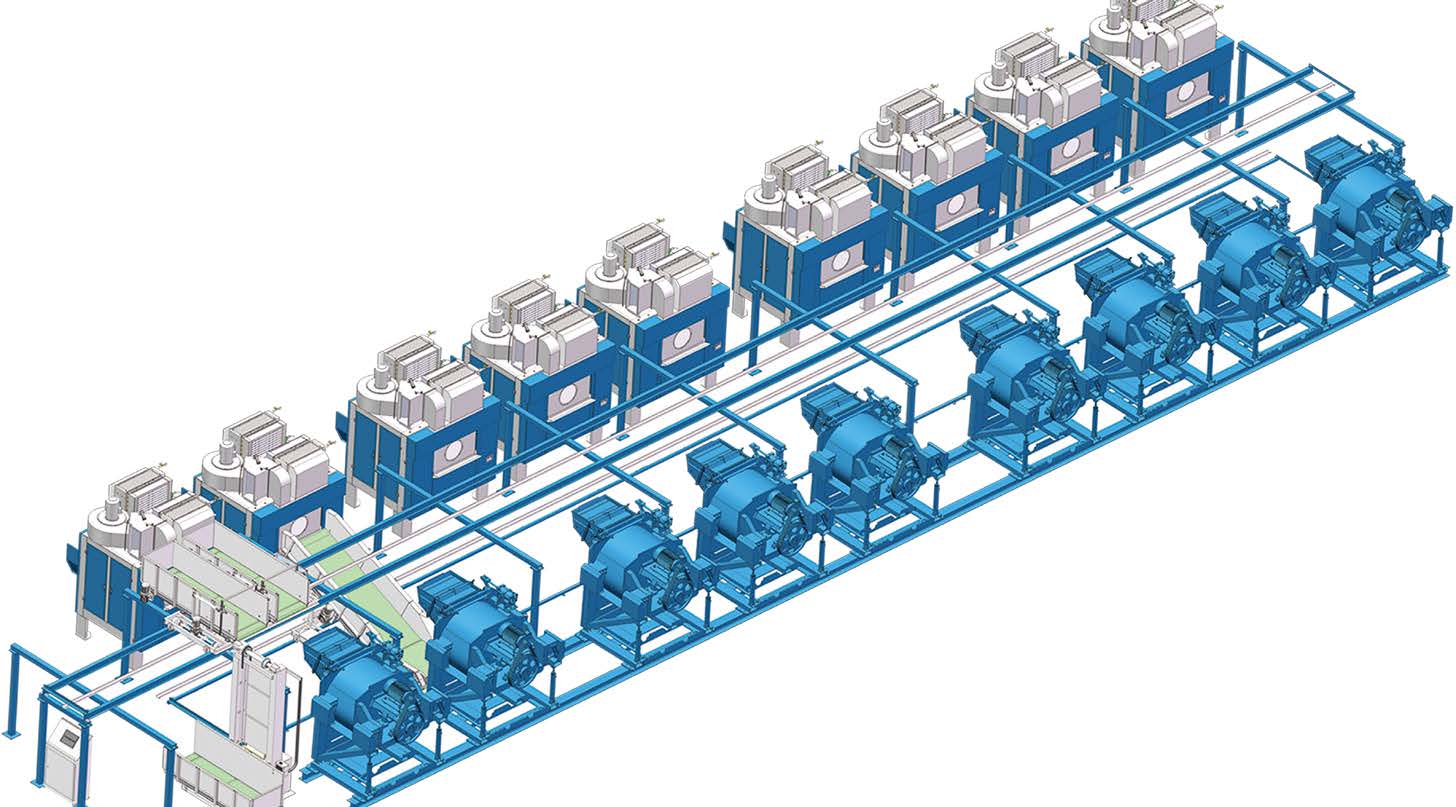

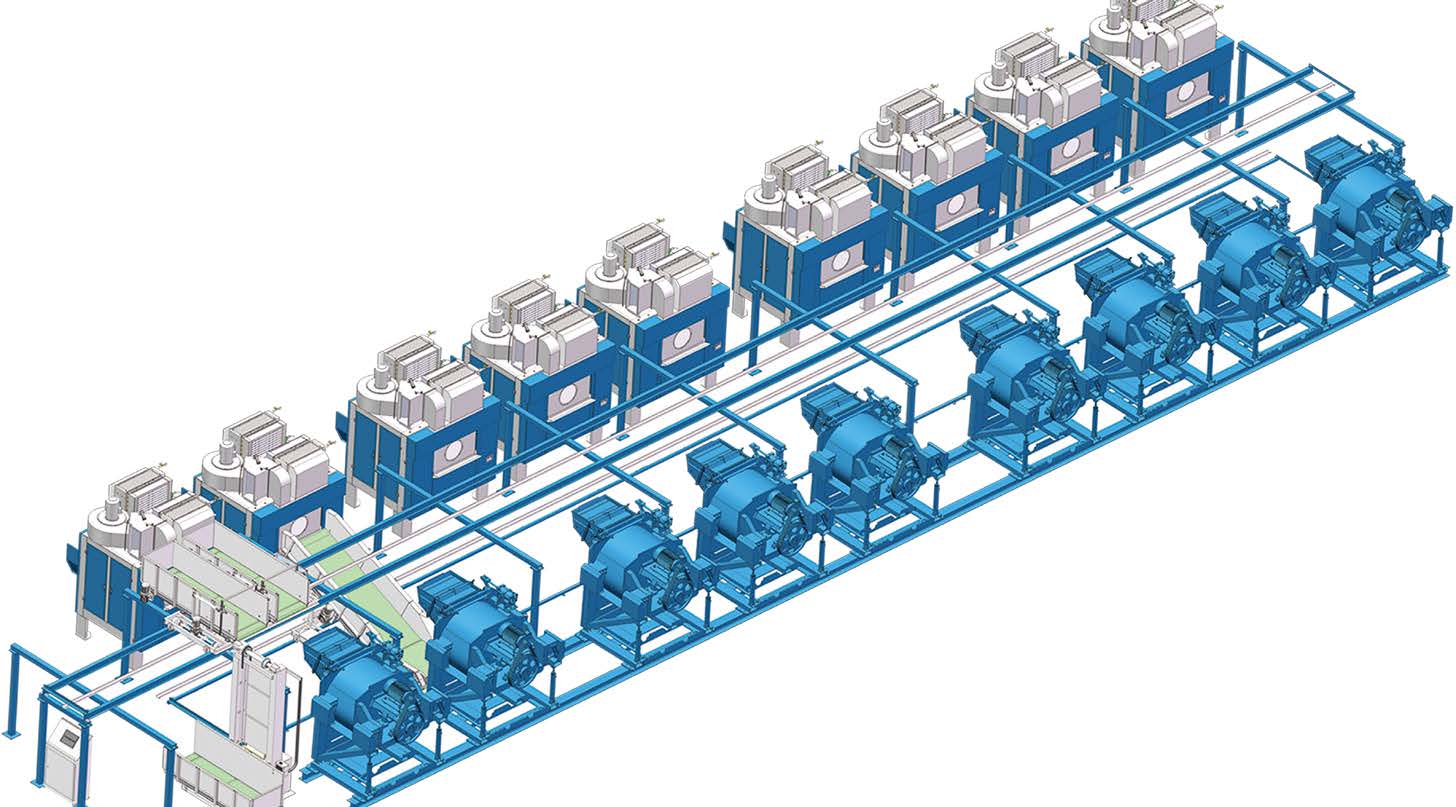

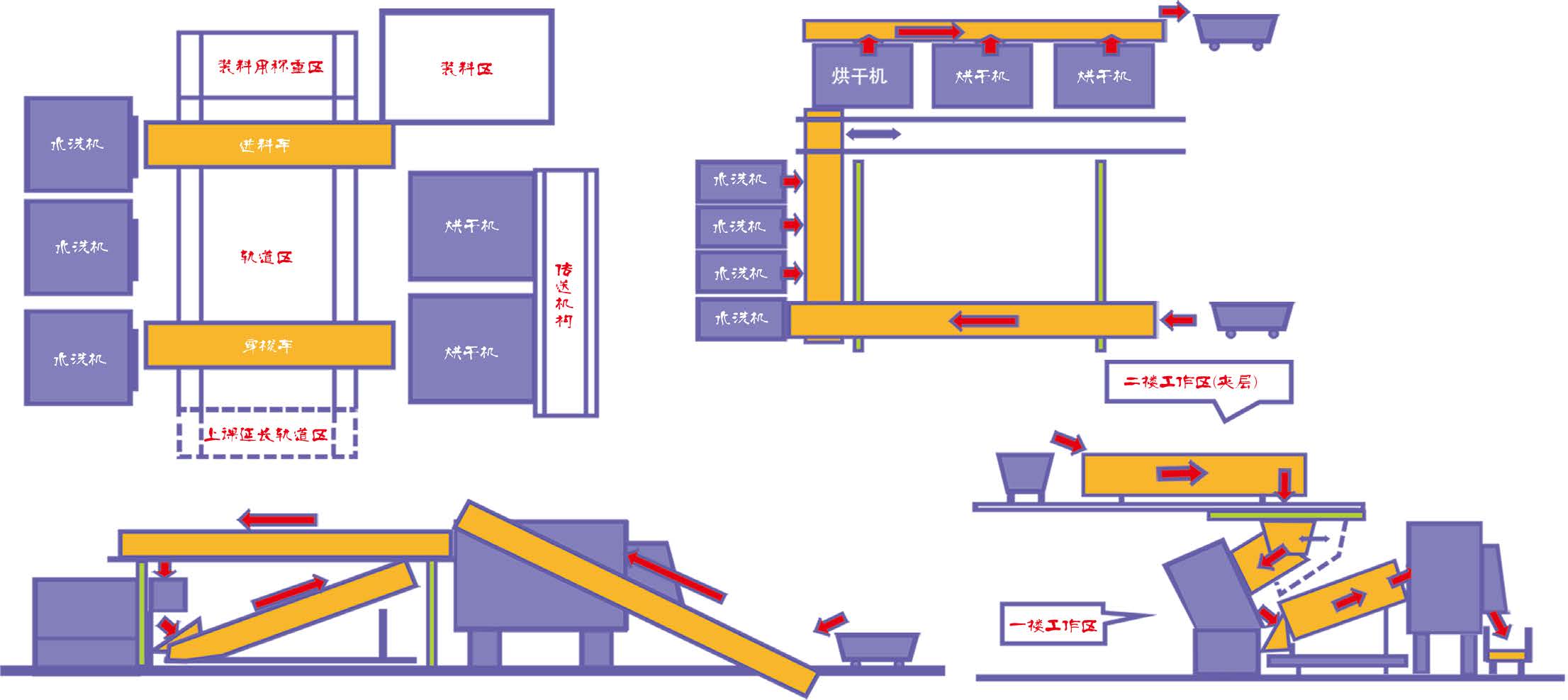

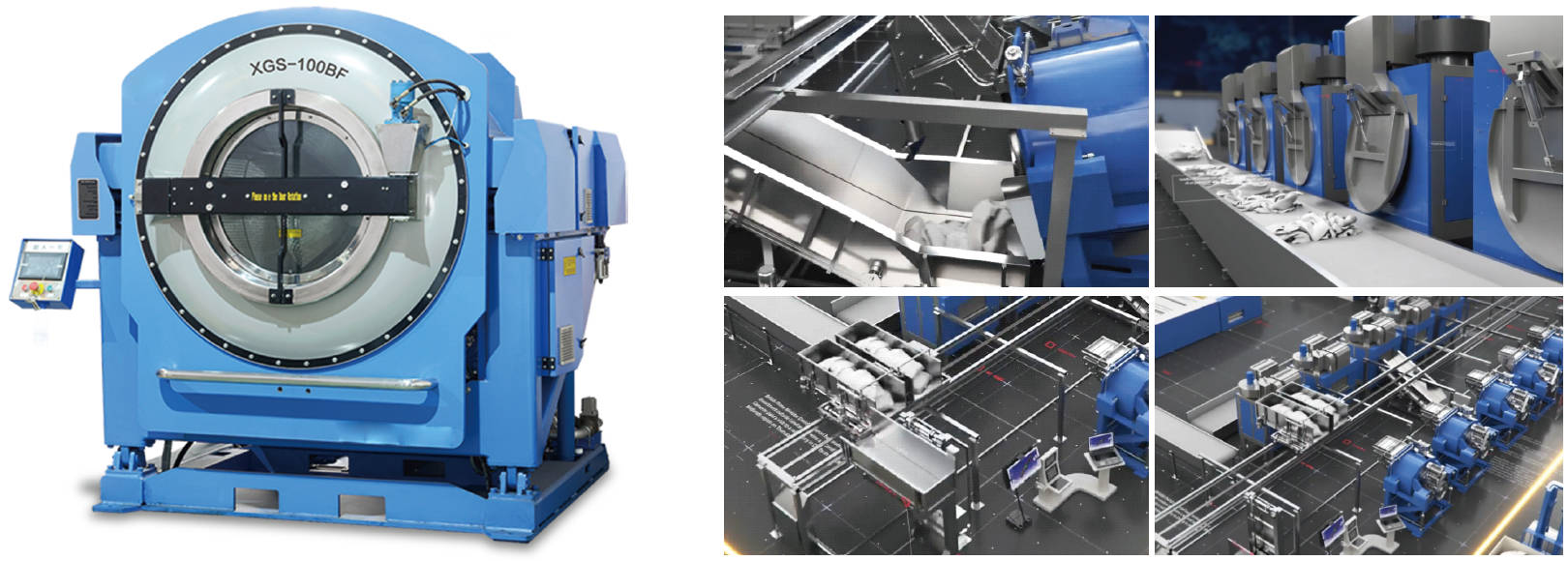

This integrated fully automatic washing system (integrated fully automated production line) is designed for large-scale washing operations. It connects individual machines through a central control system and logistics system, enabling automatic operation and loading/unloading. The main advantages include labor savings, automated operation, and high efficiency. The system offers options of single-unit capacities of 150 kg and 200 kg, with daily washing capacities ranging from 5 tons to 13 tons.

It is no longer a washing machine in the traditional sense, but anengineering device that targets the laundry room.

The integrated automation system is an automation system which is composed of several single-machine equipments through centralized control on-line. It has the functions of high efficiency and preliminary management statistics.

It can greatly improve the efficiency of single-machine equipments and save management manpower.

Guangyi Intelligent Integrated Automated Washing Production Line is not a single system, but rather a comprehensive solution comprising automation systems, energy-efficient systems, and auxiliary support systems.

Representing efficiency, energy savings, and environmental sustainability, the Guangyi Intelligent Integrated Automated Washing Production Line is poised to lead the new trend in laundry technology, once again positioning itself at the forefront of the industry.

While the system operates on a per-unit basis, which typically consumes more energy, its standard dual-drainage configuration and optional water recycling system significantly enhance efficiency. Additionally, the energy-saving dryer design reduces overall consumption by:

40% water savings

25% steam savings

10% detergent savings

Moreover, the per-unit power consumption is lower than that of traditional tunnel washers, making its energy efficiency comparable in similar load conditions.

Flexible configuration: Customized automated laundry management to meet diverse client needs

High cleaning performance: Delivers superior cleanliness tailored to varying requirements

Strong adaptability: Suitable for washing different types of linens and textiles

Energy-efficient: Compatible with various energy-saving systems for eco-friendly operation

Enhanced mobility: Ensures uninterrupted laundry operations even during equipment maintenance

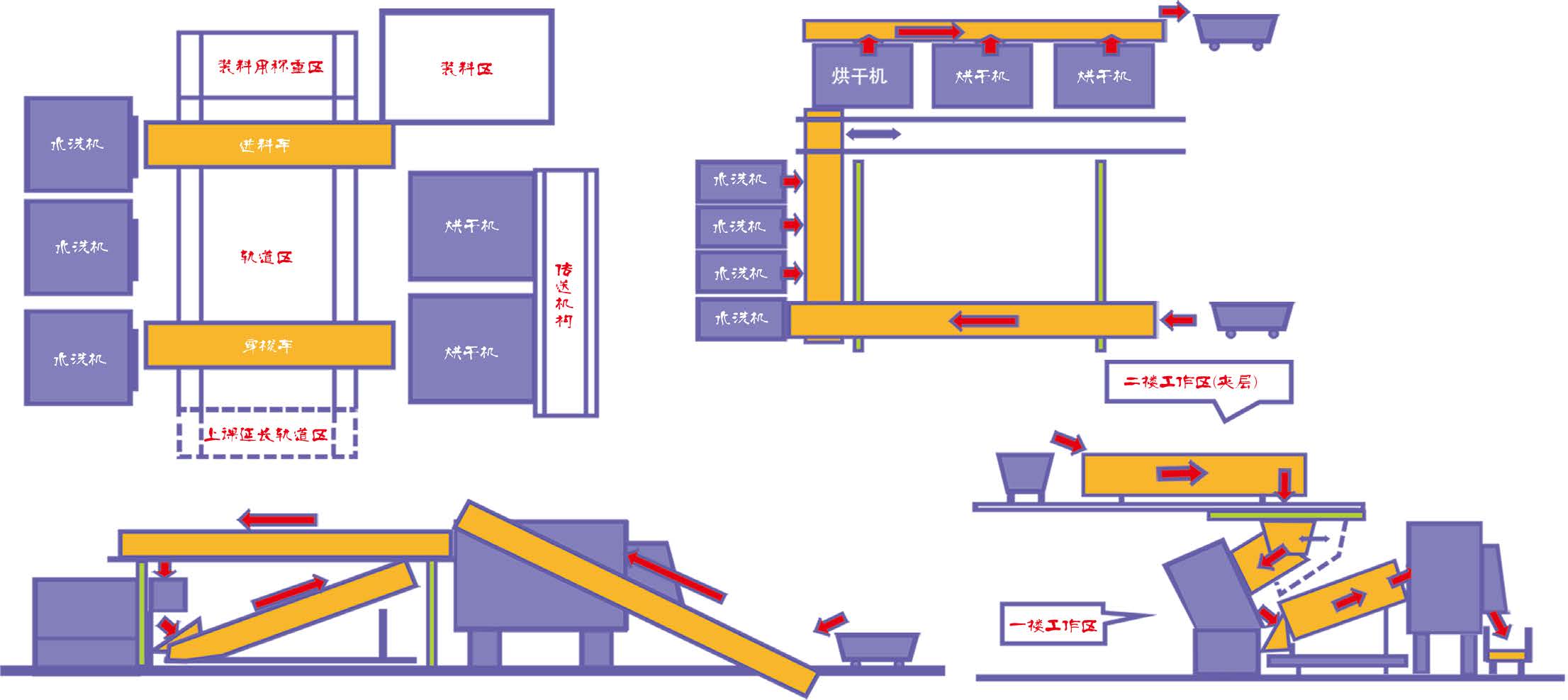

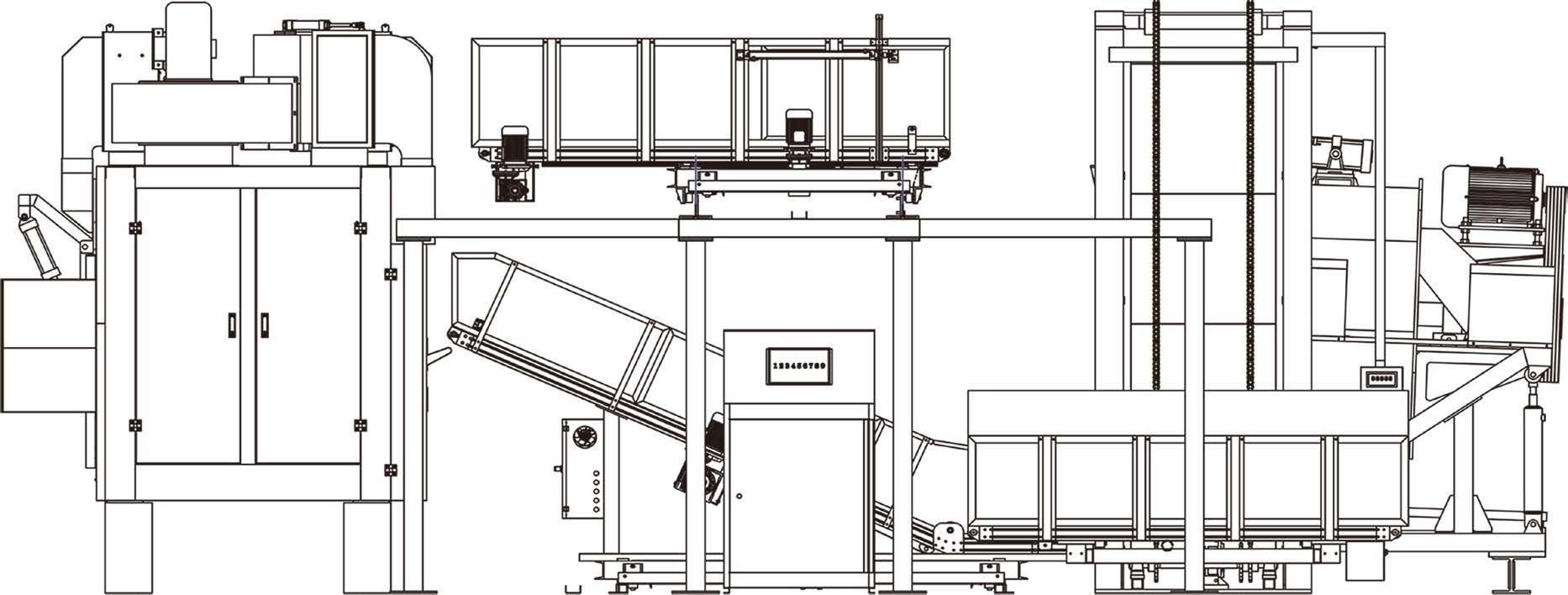

The feeding machine and the shuttle track are separated vertically, operating independently without intersection, which ensures high work efficiency.

The installation and use conditions can be met as long as the height of the workshop is below 5 meters.

It has obvious advantages in floor space and can be flexibly configured according to the actual situation of users, making it more suitable for users' personalized designs.

It can realize dedicated machines for linen washing to avoid mixed washing.

It can wash special items such as floor mats and blankets.

The linen has high cleanliness.

The linen damage rate is low.

The washing process can be switched conveniently.

It has powerful functions and high work efficiency.

The system can still operate normally even if some modules fail.

It can be flexibly configured according to the site conditions.

It can be used in combination with various energy-saving systems.

It has low investment cost and fast investment recovery.

It can realize classified washing of linen, and continuously wash different types and colors of linen.

Configuration Scheme Table of 150kg Integrated Automatic Washing Equipment

| Inclined fully automatic washing and dehydrating machine XGS-150BF | Double-door through-type dryer GTS-150 | Central control system | Weighing elevator TSJ | Loading feeder ZZJ | Shuttle conveyor CSJ | Washing capacity | |

|---|---|---|---|---|---|---|---|

| Plan One | 4 | 2 | 1 | 1 | 1 | 1 | 4.8 tons/8 hours |

| Plan Two | 5 | 3 | 1 | 1 | 1 | 1 | 6.0 tons/8 hours |

| Plan Three | 6 | 4 | 1 | 1 | 1 | 1 | 7.2 tons/8 hours |

| Plan Four | 8 | 6 | 1 | 1 | 1 | 1 | 9.6 tons/8 hours |

Equipment Configuration Scheme Table for 200kg Integrated Automatic Washing Model

| Inclined fully automatic washing and dewatering machine XGS-200BF | Double-door through-type dryer GTS-200 | Central control system | Weighing elevator TSJ | Loading feeder ZZJ | Shuttle conveyor CSJ | Washing capacity | |

|---|---|---|---|---|---|---|---|

| Plan One | 4 | 2 | 1 | 1 | 1 | 1 | 6.4 tons/8 hours |

| Plan Two | 5 | 3 | 1 | 1 | 1 | 1 | 8.0 tons/8 hours |

| Plan Three | 6 | 4 | 1 | 1 | 1 | 1 | 9.6 tons/8 hours |

| Plan Four | 8 | 6 | 1 | 1 | 1 | 1 | 12.8 tons/8 hours |

Product Consultation

+86 158-2025-1513

1744149454@qq.com

No. 2, Xinghai Road, Lanhe Town, Nansha District, Guangzhou, China

Product

News Center

Copyright